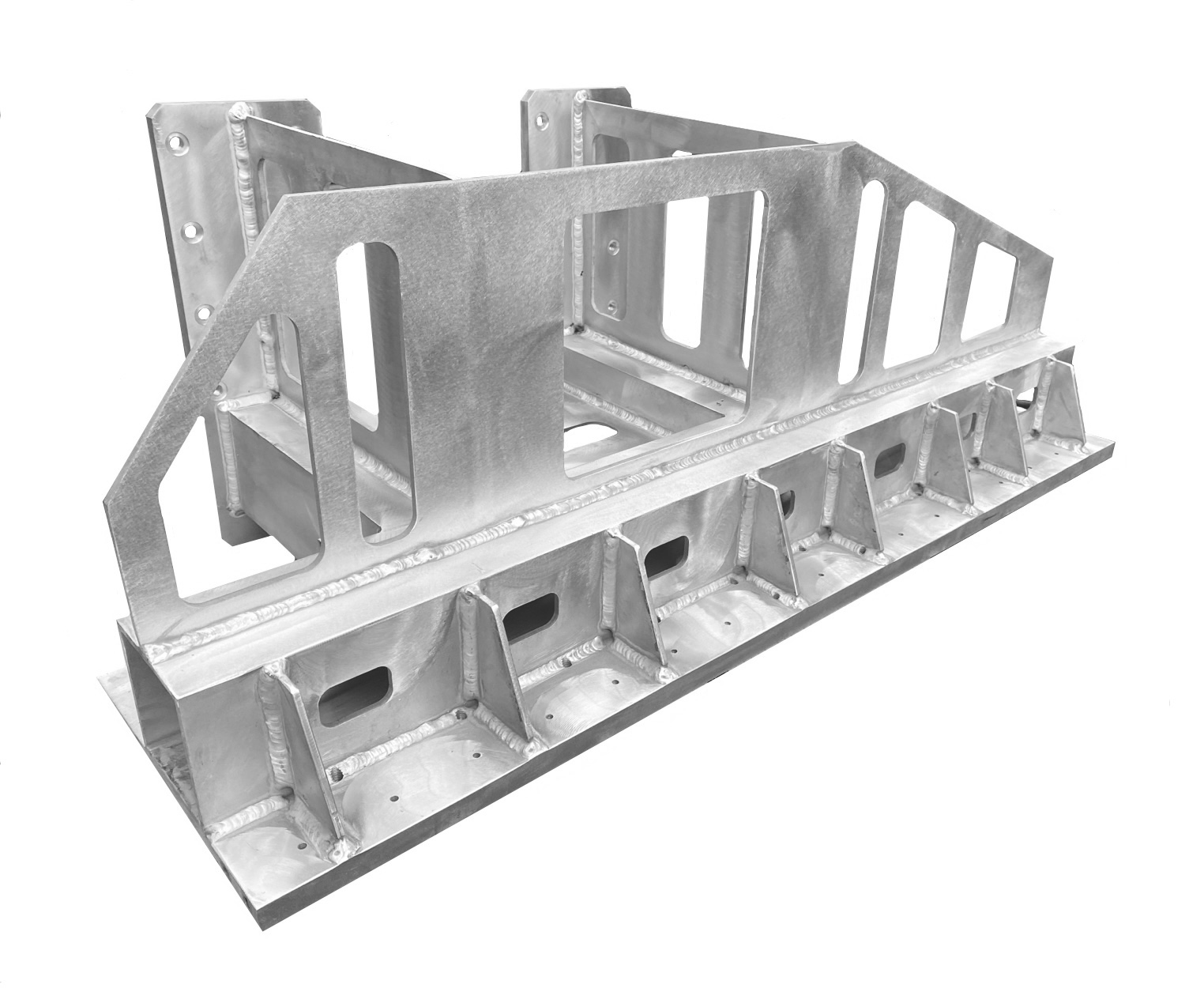

WIG-, MIG- AND MAG-WELDING

For our individual customer requirements, we have specialized in different welding processes.

With these methods we can create high-quality and precise welds and thus offer a first-class quality of our welded constructions. We distinguish in WIG welding, MIG welding and MAG welding.

Please feel free to contact us without obligation.

WIG WELDING TECHNOLOGY

WIG-welding (Wolfram inert gas) is a fusion welding process that produces very little spatter and almost no gases.

Here, the necessary current is added through a Wolfram electrode, which, unlike MIG and MAG welding, does not melt. With this method, one produces a very high quality of the weld, as the supply of a shielding gas protects against the influence of oxygen.

MIG WELDING TECHNOLOGY

The process of MIG welding (metal inert gas welding) is characterized by the use of non-active gas.

Here, we can join any non-ferrous metals together, as the gases used, such as argon or helium, do not react with the base and filler materials. Furthermore, the shielding gas prevents the risk of oxidation of the weld seam and deformations occur only in rare cases.

MAG WELDING TECHNOLOGY

MAG welding technology (metal welding with active gases) uses an arc welding process in which the material used reacts with the gases.

The advantages of this technique are a high working speed, with lower heat effects of the material and a high strength of the weld.

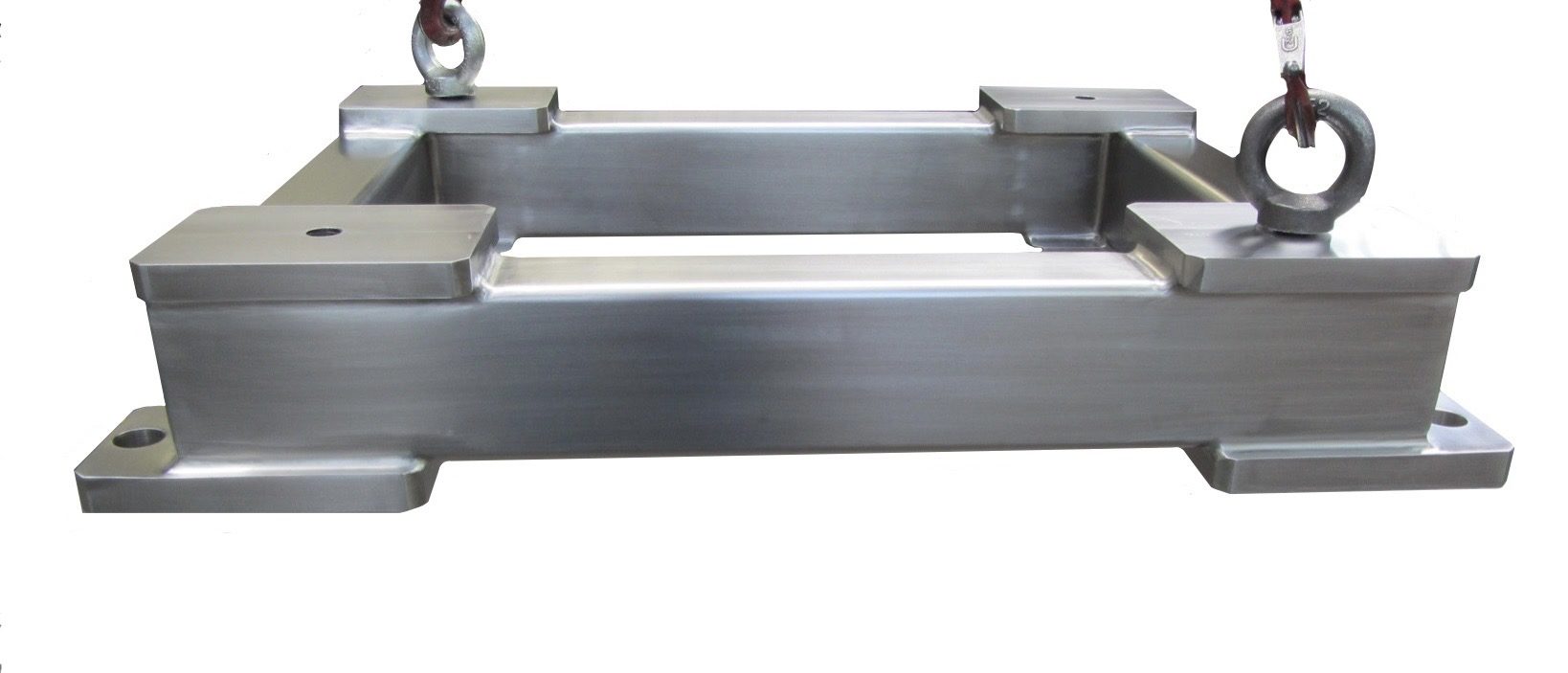

CERTIFICATE DIN EN1090-2

Our welding processes are tested and certified according to the European standard DIN EN 1090-2. Through this certification we prove a qualification of our employees as well as our technical equipment and a compliance with the specified essential product properties of our components.