Quality assurance

To ensure that our products only leave the factory with excellent quality, quality assurance or quality inspection is a particular concern of ours. Our highly qualified employees check all manufactured products with our various quality assurance systems and thus ensure that only flawless workpieces leave our premises. This quality assurance takes place with the help of various measures. Among other things, we use a highly modern and efficient 3-D measuring arm.

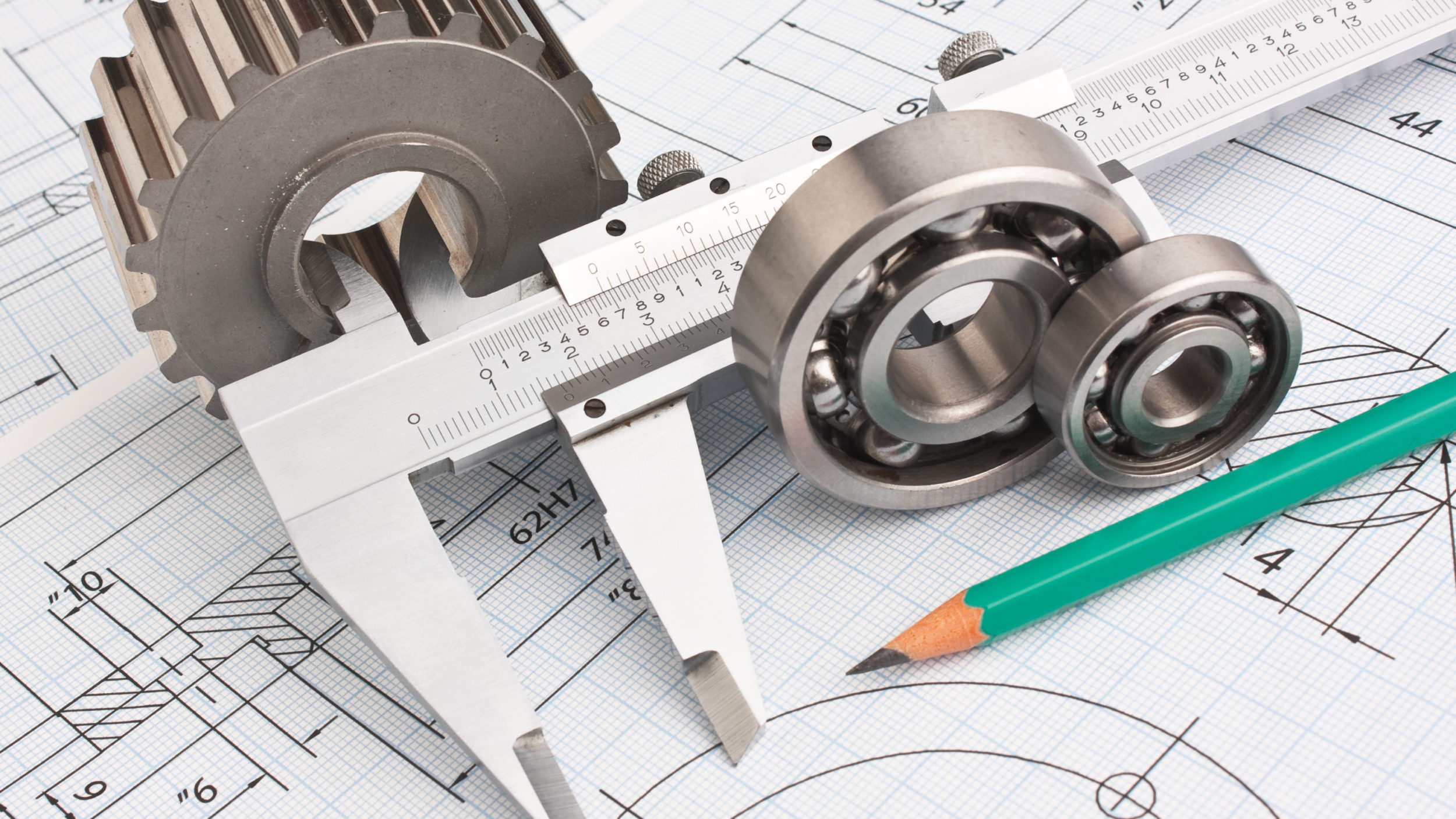

Measuring

For optimal quality control, we use a first-class and powerful 3-D measuring arm with which we can efficiently and precisely check the fitting accuracy of each component. Our employees are very familiar with the sensitive work of measuring and have many years of experience.

Of course, conventional measuring techniques are also used in addition to the inspection by the 3-D measuring arm. We find the right solution for every requirement and always offer our services at a high level.

Creating measurement protocols

When inspecting our components by means of our various measuring techniques, we create comprehensive measurement reports at the customer’s request. From these, our customers can see the required test dimensions and at the same time receive proof of the functionality of the measuring system and the proper execution of the measurement. In addition, these quality documents also serve our self-control and promote process optimization in the further course.